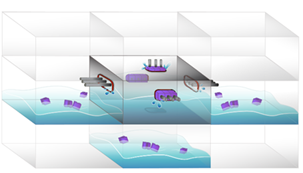

DAMAGE CONTROL SURVIVABILITY & CONTAINMENT OF FIRE, SMOKE AND FLOODING

The effective compartmentalisation of a ship is critical to the containment of fire, smoke and flooding to ensure survivability. The containment is only as strong as the weakest link; the operation and performance of WT doors, hatches, escape scuttles, cable and pipe penetrations through a vessel's bulkhead and decks play a critical role in ensuring a vessel's watertight, fire, smoke and toxicity integrity. The longer a flood can be contained in the space of origin, the greater the chance of survival. Failure of any watertight opening and / or penetration can lead to progressive flooding, therefore the functionality and performance of each component passing through a vessel's watertight deck or bulkhead is critical to ensure the safety of the vessel.

WATERTIGHT INTEGRITY INSPECTION, SURVEY, TESTING & REPAIR CSD

CSD have pioneered the use of ultrasound techniques in 2010 testing integrity of AFU radial filters, pipe and cable penetrations on HMS Albion and HMS Bulwark and were engaged to continue testing for Watertight Integrity on Hunt Class mine hunters, Type 23 Destroyers and Astute Submarines. More recently CSD have used their survey, inspection and testing expertise to test the integrity of CSD's NOFIRNO Cable Transits & Pipe Penetrations installed on the QEC Aircraft Carriers. Specialist Training in the use of the equipment in Watertight Integrity Surveys Our fully qualified team of technicians provide a number of services including: Ultrasound and detailed visual surveys of:

-

Watertight doors, hatches and escape scuttles

-

Cable and pipe penetrations

-

AFU Radial filters Repairs

Repairs

The CSD team have the skills and the experience if faults are identified, to be able to carry out the repairs necessary to ensure watertight integrity on cable & pipe penetrations and working with partner companies to rectify defects associated with watertight doors, hatches and escape scuttles. Our services, including the supply, installation and inspection of cable transits and pipe penetrations are certified by Lloyds Register QA through ISO 9001:2015 accreditation.

CSD are ISO9001:2015 certified and aim to provide the highest levels of service and support to our customers, assuring first class products and first class service whatever the industry.

CSD are ISO9001:2015 certified and aim to provide the highest levels of service and support to our customers, assuring first class products and first class service whatever the industry.

View our quality policy here.